USW atomic workers at the cleanup sites of the former Paducah Gaseous Diffusion Plant in Paducah, Ky., and Portsmouth Gaseous Diffusion Plant in Piketon, Ohio, helped the Department of Energy (DOE) reach two milestones this fall.

DOE’s DUF6 conversion project reached a turning point this month when the Paducah site shipped the first load of depleted uranium oxide cylinders onto a specialized rail car bound for a federal waste facility in Andrews, Texas.

“We commend the highly skilled, well trained, safety conscience USW-represented DUF6 workers at Paducah for exceeding all production goals,” said Local 8-550 Vice President-at-Large Jim Key. “This operation has reduced and removed the hazardous material element out of the DUF6, leaving a more stable uranium oxide at relatively the same assay content it was when it was originally removed from the ground.”

Key attributed this success to the knowledgeable, former gaseous diffusion operating personnel. He said they transferred their historical operational experience to the DUF6 facility. The local represents 130 workers engaged in the DUF6 project at Paducah.

DUF6 is a coproduct of the uranium enrichment process that operated at the Paducah and Piketon sites. Both sites have cylinders of DUF6 stored onsite that are waiting to be converted into a stable form for shipment. The DOE says there are about 800,000 metric tons of DUF6 at the two sites.

The Portsmouth DUF6 inventory is expected to be processed in about 18 years and Paducah’s larger inventory within 30 years.

Parallel operation

The DUF6 conversion project operates at the Piketon plant as well, and Local 1-689 represents the 130 employees who work on that project.

Local 1-689 President John Knauff said that many of the workers who started up the DUF6 facilities came out of the diffusion plant operations.

“We negotiated these opportunities for people to move into these new facilities like the DUF6,” Knauff said. “It’s their experience that made this success possible.”

Tom Lamerson, a Local 1-689 division 2 committee person, was one of four shift engineers who got the DUF6 plant up and running. Once it began operations, he joined the union in 2014 as a control room operator.

The conversion process involves separating cylinders of depleted uranium hexafluoride into depleted uranium oxide and hydrofluoric acid. The depleted uranium oxide is a more stable chemical form that can be reused, stored or disposed of, and the hydrofluoric acid is sold for industrial use.

Lamerson said the Piketon plant is in the planning stages of shipping its depleted uranium oxide to the Texas waste facility.

“It’s good to be able to start shipping these cylinders of oxide powder to the desert where it’s less populated. So, we’re happy to see those cylinders get out of our plant and out of our community.

“You feel you’re doing a huge service to the community, the environment and the country. We are getting rid of it safely and efficiently,” Lamerson said.

Second waste achievement

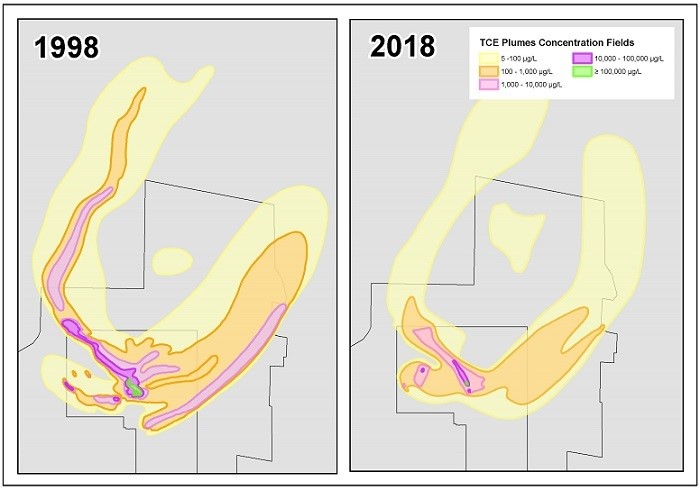

At the pump-and-treat operations at the Paducah plant, the DOE marked 25 years of successful operations in removing groundwater contaminants, largely trichloroethene (TCE). TCE is a common industrial degreaser that the plant used to clean equipment.

To date, the site has treated about 4.4 billion gallons of water—an amount equivalent to filling 6,500 Olympic-sized swimming pools. As of early 2020, the pump-and-treat systems removed more than 4,100 gallons of TCE from local groundwater.

Key said that about 50-75 members work at the pump-and-treat operations.

“The USW Local 550 union leadership is extremely proud of and commends their highly-skilled, well-trained, safety-conscience, represented workforce in this successful project to remove the hazardous elements from the groundwater table,” Key said.