When hand sanitizer became scarce at the beginning of the coronavirus pandemic, it did not take long for Local 13-12 members and other non-represented employees at the chemical plant to realize the great opportunity they had to assist health care workers and first-responders combat COVID-19.

ExxonMobil’s Baton Rouge Chemical Plant in Louisiana has the largest single IPA unit in the world of this key ingredient in hand sanitizers and disinfectants.

“We were concerned that we were going to run out of hand sanitizer because there were none on the shelves,” said Buford “Bobby” Mitchell, a 14-year chemical operator and member of Local 13-12, who works at the IPA unit.

“We have the stuff here, so why don’t we make it?”

Management thought it was a good idea, so employees formed a team to bring the idea into fruition. Piping modifications had to be made.

“We had to bring up another section of the IPA unit that had not run for nine years,” Mitchell said.

Feedstock to make IPA comes from ExxonMobil’s refineries. The company buys other ingredients to mix with the IPA and form medical-grade hand sanitizer.

“Every batch is analyzed by our lab to U.S. FDA (Food and Drug Administration) specifications,” Mitchell said.

The FDA set up guidelines for non-traditional manufacturers to make hand sanitizers. ExxonMobil also had to work with the state of Louisiana and the department of health before production began because hand sanitizer is a registered drug.

Packaging challenge

Packaging the hand sanitizer also involved creative thinking and teamwork. Normally, Local 13-12 members blend and package Mobil-branded lubricants at the Port Allen Lubricants Plant, located across the Mississippi River from ExxonMobil’s Baton Rouge refinery and chemical plant complex.

Employees had to adjust the bottling process, including the design of a semi-automated machine to fill six quart-sized bottles of hand sanitizer at a time.

Employees had to adjust the bottling process, including the design of a semi-automated machine to fill six quart-sized bottles of hand sanitizer at a time.

Within a couple of weeks, Local 13-12 members were producing medical-grade hand sanitizer to donate to health professionals, first responders, charities and the military.

Such a task normally is accomplished over months, said J. Dow, who leads the polymers process department at the chemical plant, to local media.

“It was a huge feat. All of us worked together and it went off without a hitch,” Mitchell said. “It makes you proud as a USW-represent employee. I was proud as a peacock.”

First batch donated

Workers produced the first batch of 160,000 gallons of medical-grade hand sanitizer—enough to fill almost 5 million 4-ounce bottles—for health care workers and first responders in Louisiana, New Jersey, New Mexico, New York, Pennsylvania and Texas.

Mitchell’s wife, Kim, an intensive care unit (ICU) nurse at Baton Rouge General Hospital, and her coworkers were among the first recipients of this first batch, and its arrival ended their hand sanitizer shortage.

“Before COVID-19, the hospital had two ICUs. During the pandemic, the hospital ran six ICUs: three for coronavirus and three for non-coronavirus patients. The supply of hand sanitizer was in great demand, and we were short of it,” Kim said.

She said all the mounted hand sanitizer canisters were empty and refills were not arriving. To make do, she and her coworkers had to use squish bottles of sanitizer.

“With ExxonMobil providing our hospital with a large amount of hand sanitizer, we all have ready access to it,” she said.

Production ramped up

Exxon increased its IPA production by 3,000 tons per month in April, which equals about 50 million four-ounce bottles of hand sanitizer.

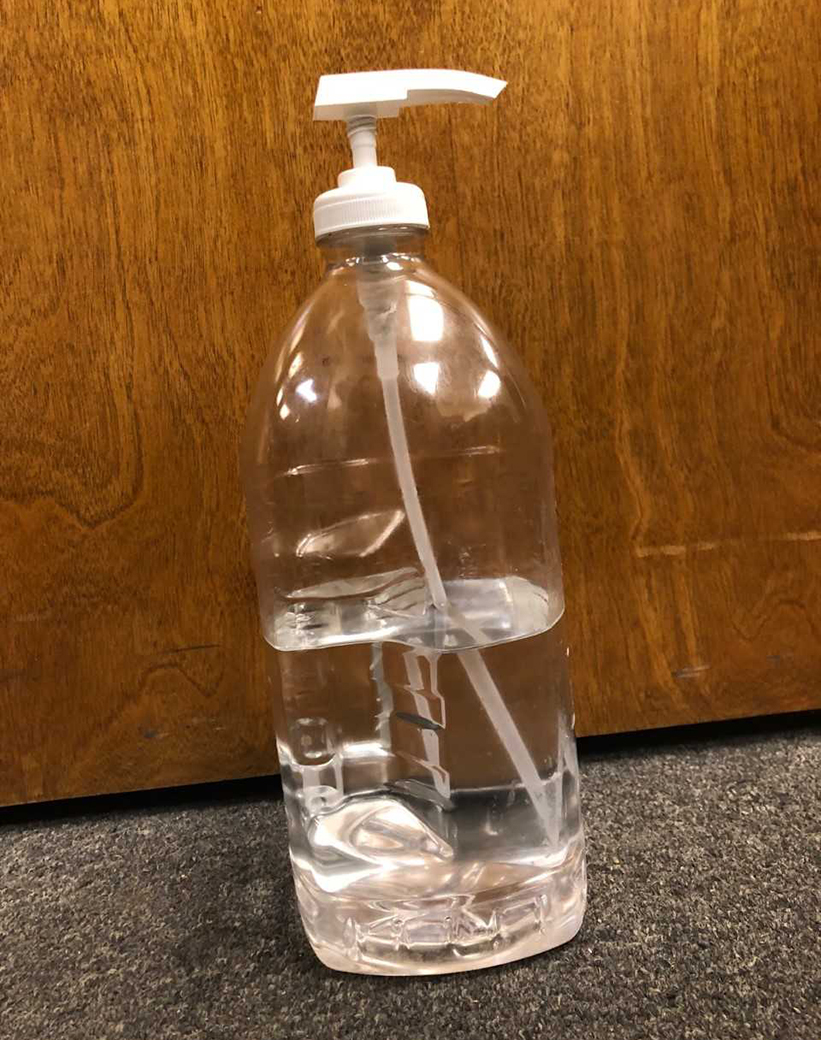

Now, employees can fill up a limited number of empty bottles with the hand sanitizer they produce at no charge. Each Baton Rouge facility has several stations that have sanitizer in tote containers.

ExxonMobil contributes to the fight against COVID-19 in other ways as well. The company increased its manufacturing capacity to produce specialized polypropylene, which is used in medical masks and gowns. It ramped up production to make up to 200 million medical masks or 20 million gowns.

The company also technically collaborates with the Global Center for Medical Innovation to rapidly redesign and manufacture reusable personal protective equipment, such as medical face shields and masks.